Contents

- Definition of a balcony (for warranty purpose)

- Limitations of this guidance

- Design requirements

- Installation and testing requirements

- Operations and maintenance

- Balcony detailing and recommended approaches

- References and further guidance

Definitions

A balcony is a building component which is an accessible external amenity platform above ground level which is exterior to and with direct access from a building. A balcony can project beyond the walls of a building; it can be formed within a recess of a building; or it can be a hybrid of both as further explained below. A balcony does not form part of the thermal envelope, e.g. not forming a roof. This guide relates to balconies and not terraces and the guidance relating to roofs in the technical manual should be followed where a ‘terrace forming a roof’ is proposed.

Projecting balcony

An accessible external amenity platform affixed to the exterior of a building above ground level exterior to and with direct access from a building.

Enclosed balcony, or inset balcony

Accessible external amenity platform that is protected from rain ingress by a roof or balcony above and a wall(s) or weather screen to the sides.

Semi-inset balcony

An accessible external amenity platform affixed to the exterior of a building which is in any way set back into the main wall line or thermal envelope of the elevation. Where this forms part of the thermal envelope the designer will need to for the purposes of the drainage design consider this to be a roof terrace.

Roof terraces

A roof terrace is a roof with general pedestrian access. It may form a floor which may be utilised for use and enjoyment of amenity or maintenance activities. A terrace is a roof for the purposes of waterproofing and the design of waterproofing and drainage. Guidance in the technical manual relevant to flat roofing should be followed to meet the relevant functional requirements.

Attention should be drawn to regulations regarding combustibility for the outer weather screen in terms of The Building (Amendment) Regulations 2018, Regulation 7(2).’ e.g. laminated glass/ fire tests for systems.

Winter garden

An enclosed balcony is sometimes referred to as a “Winter Garden”. Due to the variation in levels of enclosure these can be in some cases considered a habitable room and care regarding the assessment of key criteria such as structural robustness, escape from fire and potential fire spread, condensation risk and moisture penetration, acoustics, ventilation, heating and cooling, protection from falling and safe breakage including appropriate glazing specifications, thermal performance and accessibility will need to be assessed on a case by case basis.

Limitations of this guidance

The guidance is not prescriptive and provides an outline as to approaches which when considered on a site specific basis may be deemed acceptable and following the guidance provided, the project team must be aware that it is not a guarantee of acceptability in its own right.

This update will provide technical guidance regarding the common types of balconies and the key risks to consider in the design and strategies to overcome those risks.

This guidance focuses on buildings which has: six storeys or greater, rather than buildings that have a storey height greater than 18m as defined in Diagram D4 of Approved Document B: Volume 1.

Also:

- For warranty purposes, all proposals for above-ground attenuation surfaces are considered on a case-by-case basis due to the developing nature of guidance available.

- This guidance is not intended as a standalone design guide and is intended to supplement the Technical Manual and does not include full details of what must be considered to comply with other associated design guides.

- The Technical Manual and the functional requirements which are to be met can be found here.

- Loadings applied must be checked and approved by the structural engineer for the design.

Deflection must be considered by the designer as part of the overall design.

Design requirements

As a minimum, the design team should prepare the following drawing for review:

1. Balcony plan and section detail including consideration of structural connection to the building, threshold detailing including:

a) Weatherproofing and support of the threshold,

b) Provision of thermal breaks,

c) Drainage fall direction(s),

d) Outlet location(s),

e) Overflow location(s)

f) Details of the provision of pedestrian surface support structure where appropriate

g) Details of the provision of guarding including parapet walls and balustrading used as guarding, should be designed in accordance with BS EN 1991-1-1 to resist horizontal loading and as required by the building regulations

2. Structural Design package.

3. Submission of 3rd party accreditation documentation for the products proposed and where materials are specified, provide detail as to how the structure will achieve the functional requirement of a 60 year lifespan.

Meeting building regulations

The designer must ensure that requirements relating to all building regulations are achieved. The designers attention is particularly drawn to Approved Document A, B, C, E, F, H, K, and M in relationship to balconies and compliance with these requirements through the employment of the guidance in the relevant Approved Document or referenced guidance within that Approved Document when appropriately applied will tend to support a suitable design approach.

The developer and the builder must comply with building regulations and the authorised building control body involved inspects their work. In undertaking the inspections and performing their role, the surveyor is not assuming any duty or responsibility or assurance that the work has been completed to any particular standard.

Warranty limitations

The designer must be aware of the specific scope of the LABC Warranty policy in context of the limitations of the Technical Manual guidance compared with additional requirements contained within other standards e.g. BS 8579: 2020, which may extend beyond the scope of our requirements. The designer may consider their own design, aims beyond the minimum requirements of the Technical Manual in any specification and in this instance BS 8579: 2020 may be consulted by the designer. The aim of this guidance is to highlight the minimum requirements relating to the design and construction of balconies against the requirement of the Technical Manual.

Guidance relating to all balcony types

Weather tightness, upstands, and fall

The key to the successful incorporation of any balcony is the detailing and construction of the interface with the building envelope. Upstands and comprehensive detailing ensure the building is protected from water ingress and the damaging effects of poorly controlled water.

Falls to a minimum of 1:80 are to be provided to all balcony drainage types to promote moisture migration. Where falls are created, screeds may be employed. Screeds might be of heavy or lightweight aggregate, and be cement or bitumen-bonded; the added weight of a screed increases deflection of the slab. The insulation value of a lightweight screed should be taken into account when assessing the risk of interstitial condensation.

The recommended thickness of a cementitious screed-to-falls bonded to a concrete slab is 40 mm nominal (25 mm minimum at any point) and the construction of upstands should take into account the necessary thickness of the screed. For thinner, liquid based screeds such as Poly Methyl Methacrylate (PMMA) screeds may be considered for use with typically reduced thicknesses when compared with cementitious screeds but must be carefully specified and applied in line with the manufacturers requirements.

Structural durability

The structure of the balcony is considered part of the home and therefore the functional requirements relating to durability of the structure of a balcony will apply, namely: The structure shall, unless specifically agreed otherwise with the warranty provider, have a life of not less than 60 years. Individual components and assemblies, not integral to the structure, may have a lesser durability, but not in any circumstances less than 15 years.

Resultantly, components transferring load from parts of a balcony to the main structure of the building should have a service life equal to that of the primary structure of the building which for the purposes of warranty. Care and attention is needed to check that protection coatings for lightweight construction are appropriately specified.

For example, hot dip galvanising to BS EN ISO 1461 with a minimum average coating of 85μm on steel of 6mm or more thick has an average life expectancy of more than 50 years in the UK in low exposure conditions. Due diligence will need to be shown in material selection to ensure durability is appropriately specified.

Attention will be required in order to ensure that the materials used are suitable to achieve the intended lifespan. For example, materials should be suitably protected against corrosion, see ‘Appendix C - Materials, Products, and Building Systems’ of our Technical Manual for further information.

A detailed design will need to be provided to evidence that the balcony structure and its affixation to the main building will be suitably provided. A testing and quality assurance plan for fixings, including those related to the balcony should be discussed with your Major Projects Manager.

Wind and vibration

Lightweight support structures, such as free-cantilevered steel balconies, can be prone to vibration due to wind or people movement. Structural engineers must take account of potential vibration effects due to orientation or location of balconies.

For buildings taller than 50 m, or with unconventional (e.g. non-rectangular) layouts, or in close proximity to other tall buildings, net wind pressures on guarding should be determined through detailed scale-model wind tunnel tests in accordance with BS EN 1991-1-4, its UK National Annex, NA to BS EN 1991-1-4, and PD 6688-1-4. Where glazing is provided, wind load calculations should be provided prior to glazing design’ for any building height/coastal location.

Fire safety

It is noted that national variances in building regulations exist across the UK. The overarching principle is to engage with the building control body relevant to that nation to ensure that the building regulation requirements are met. It is recommended as a starting point that the designer is to ensure that any constituent materials of the balcony contains materials of European Classification A2-s1, d0 or A1, classified in accordance with BS EN 13501-1:2018 unless directed as exempt under Regulation 7(3) of The Building (Amendment) Regulations 2018. Where the approach is proposed to be varied this must be made clear to LABC Warranty as early as possible.

A key risk includes ensuring the appropriate specification of compartmentation at the slab edge. The designer is recommended to provide an outline coordination elevation drawing to allow for setting out and understanding of the conflict that may occur between the various interfaces between the balcony structures, to ensure that potential clashes are anticipated.

Balconies supported by brackets fixed back to the structure of the building, passing through the wall cavity must ensure that fire separation is continuous and that no routes for the passage of smoke, flame or hot gases are created. Any such design shall only be suitable where test evidence exists to prove the performance of the bracket in continuation of the fire performance across the whole of the area where the balcony adjoins the building.

Please consult Local Authority Building Control or your building control body to ensure that all products in the balcony meet the necessary building regulation requirements. It is recommended a table listing each and every component product, the combustibility rating of that product and the test evidence or third party accreditation is recorded.

Thermal performance

Where a balcony or terrace structure is formed as a contiguous part of the building structure, the interface between the balcony structure and the adjacent floor structure is most likely to be a geometric linear thermal bridge. If the surface temperature factor (fRSi) is controlled incorrectly, thermal bridging is likely to result in condensation and mould growth problems. Appropriate thermal breaks must be specified in this location and 2D thermal analysis for simple junctions or 3D for complex junctions, ensuring that the surface temperature is controlled.

Similarly, where a balcony or terrace structure is formed as a contiguous part of the building structure, the interface between the balcony structure and the adjacent floor structure is most likely to be a geometric linear thermal bridge and thermal separation is to be provided. Resultantly thermal breaks are likely to be required in this location. It is the responsibility of the designer to ensure condensation risk is sufficiently mitigated.

Specification of safeguarding

All guarding forming fall arrest from height, including walls used as guarding must be designed in accordance with BS EN 1991-1-1 to resist horizontal loading and as required by Part A, B, K and M of the Building Regulations.

Guidance on the design of barriers is given in BS 6180, and this Standard is referred to in Approved Documents K for both England and Wales, and in Technical Booklet H for Northern Ireland. The Technical Handbooks for Scotland do not refer to BS 6180 in the section on barriers.

Require barrier height

For England and Wales, Approved Document K requires protection at any change of level of at least 600mm in dwellings, or 380mm (or the height of two risers on stairs) in buildings other than dwellings. In a non-dwelling it is reasonable to assume that building users may be less familiar with the building, and that there are more likely to be crowds, hence the more stringent requirement.

Table 1 of BS 6180 specifies minimum barrier heights for various circumstances as follows:

|

Use

|

Position | Height |

|---|---|---|

| Single-family dwelling |

Barriers in front of window | 800 mm |

| Stairs, landing, ramps, edges of internal floors | 900 mm | |

| External balconies including Juliette balconies, edges of roofs | 1100 mm | |

| All other uses |

Barrier in front of window | 800 mm |

| Stairs | 900 mm | |

| Balconies and stands, etc. having fixed seating within 530 mm of the barrier | 800 mm | |

| Balconies and stands, etc. having fixed seating within 530 mm of the barrier, providing sum of the barrier width and the barrier height is greater than 975 mm | 750 mm | |

| Other positions including Juliette balconies | 1100 mm |

Care and attention is raised with elaborate designs and it should be ensured guarding is not climbable.

For buildings where likely users include children under five years of age, regulations state that there should not be gaps in balustrades which permit a sphere of 100mm to pass through.

Glazed barriers

Glazed barriers will require a nominated person to undertake a site specific design to ensure that the design of the guarding for the scheme is suitable and due diligence has been demonstrated. For glazed barriers there are four important criteria for the designer to satisfy:- The barrier/glass should have sufficient strength to resist the design loads with an appropriate factor of safety.

- The displacement of the barrier, under load, should be within acceptable limits for human comfort.

- The barrier/glass should have reasonable resistance to accidental impact.

- The post-failure behavior of the glass in a barrier should be safe and, if necessary, failed glass should retain some residual strength to preserve life safety.

- The designer should clearly demonstrate how containment of the glazing will be achieved.

- The designer should consider the risks associated with nickel sulphide inclusions in toughened glass and the combustibility of any interlayer for laminated glazing.

A detailed design pack is to be submitted to demonstrate how these criteria will be satisfied as part of the risk management process.

Drainage approaches

Drainage is defined in this context as the management for the dispersal of water. A form of water management is required on all balconies, regardless of their surface area which may be either:

Positively drained - water is collected on a waterproof surface and directed to a piped outlet into the wider drainage network. A method of warning occupants in the vicinity of the building where a blockage arises in a positively drained approach where water is collected through the use of a conspicuous overflow pipe.

Edge drained - a design approach which allows water to quickly pass through a pedestrian surface through to a soffit collection tray or impervious surface laid to falls where it is momentarily collected and drained away from the weatherproof envelope of the building so that it does not cascade onto another balcony and discharges to a lower level where the water is appropriately managed.

Free drained - where a free draining approach is used, water is not collected on a membrane or impervious surface, such as a soffit collection tray but designed to instantly dissipate through a number of perforations in the balcony substrate to atmosphere so that it does not cause a risk of water ingress to the weatherproof envelope.

Products where proposed, are to be provided with 3rd party accreditation and used appropriately according to the proposed drainage approach employed. Materials where specified to provide a certain level of durability may require additional verification certification to demonstrate the required level of performance will be achieved to meet the Functional Requirements of the Technical Manual.

Balcony types

These different approaches are only suitable based on the type of balcony proposed. These are outlined in detail as follows.

1. Inset or semi-inset balcony drainage

Requirements:

- All inset or semi inset balconies must be positively drained. Other drainage approaches are not acceptable in this arrangement.

- Balconies must be provided with a structurally stable substrate, which has been suitably prepared to receive a waterproofing product and suitably prepared to ensure proper adhesion i.e. remove laitance and dust.

- A structural upstand with a fully bonded waterproof outer membrane or coating, with sufficient 3rd party accreditation for that use of at least 75mm are to be provided where level thresholds are required,

- A structural upstand with a fully bonded waterproof outer membrane or coating, with sufficient 3rd party is to be provided to the balcony side or “cheek” walls.

- The threshold sill is to be adequately supported to ensure that the dynamic load of any pedestrian traffic can be suitably supported over the long term.

- Thermal breaks are to be provided at any perimeter to the thermal envelope of the building.

Sufficient insulation is to be provided to avoid cold bridging and reduce the risk of the potential for surface and interstitial condensation. - Finished falls of at least 1:80 are to be achieved at the waterproofing level to ensure that water is able to reach an outlet. Standing or ponding water is not acceptable and water must not backfall.

- The pedestrian surface where provided on a separate subframe or pedestal deck system must be provided with a 10mm gap at the threshold and any adjacent walls.

- Sub frames or pedestal deck systems must be designed to mitigate the potential risks of point loads on the waterproofing product which could cause localised degradation to the waterproofing system.

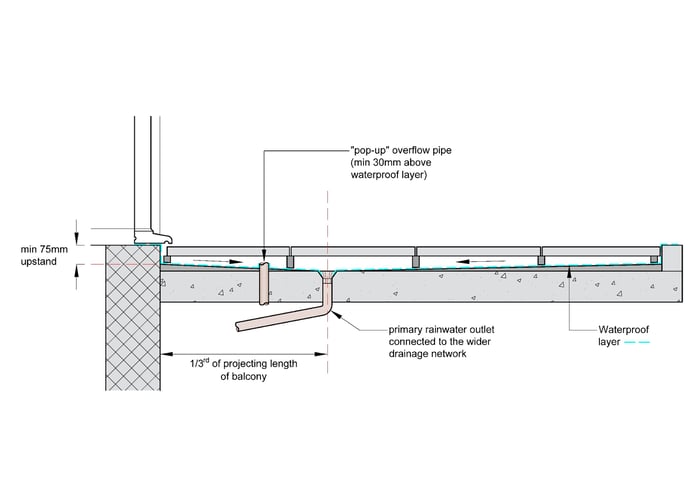

- At least one countersunk outlet of sufficient sizing is to be provided, typically 110mm will be suitable for a single balcony. Where extensive, balconies may require the submission of micro drainage calculations to BS 12056-3.

- Outlets must be countersunk and positioned at least 1/3 or 1m of the length of the balcony away from the threshold of the door or perpendicular to the door, whichever is the greater.

- At least one conspicuous overflow is to be provided to ensure that in the event of a blockage, water does not cause a risk to the threshold upstand to any door or opening becoming overwhelmed. A conspicuous overflow will ensure that in the emergency situation that the outlet is blocked, awareness is raised and it can be cleared quickly. Spillover style overflow approaches should be avoided for this reason. Typically a pipe of at least 50mm diameter protruding up at least 30mm from the waterproofing level surface datum will be a suitable provision.

- The design must ensure that no storm water is discharged from balcony to balcony or roof to roof. At the leading edge, a suitably designed upstand kerb can assist with this aim and provide a fixing point for guarding.

- Materials and produced must be provided with 3rd party accreditation to ensure their suitability for use.

Recommendations for inset or semi-inset balcony drainage

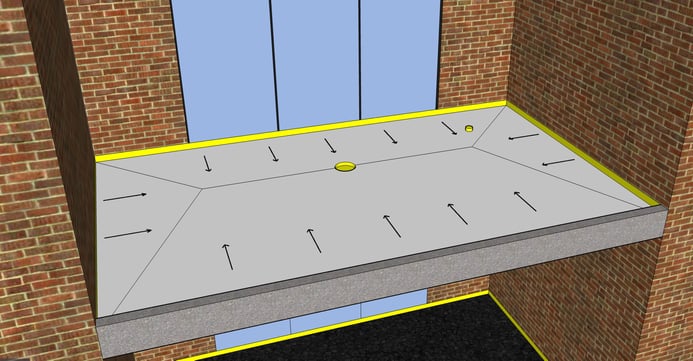

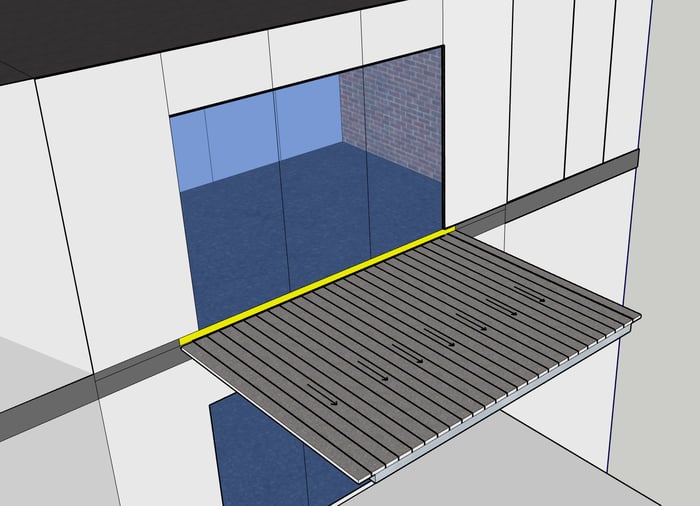

The below diagram is one which demonstrates how the principles in this guidance could be applied to produce an acceptable design for an inset balcony:

Red line shows 1/3 of projecting length of balcony. Details relating to pedestrian surface and guarding omitted for clarity.

Yellow denotes upstand. Mitre approach above may assist the designer to minimise build up height for falls.

The outlet should not be positioned adjacent to the threshold. It is recommended that the outlet is positioned at any point between the leading edge and 1/3 of the length of the balcony from the threshold as per the below detailing.

A conspicuous overflow should be provided. It is recommended a “pop up” overflow pipe protruding 30mm above the waterproofing layer is provided. It should be positioned in the zone between the threshold and 1/3 of the projecting length along the balcony. It may be offset to the side. The ‘telltale;’ overflow should discharge to the balcony below to allow for notification of the building management that the primary outlet is blocked. The capacity of the overflow should be not less than that of the outlet.

Over flows should be positioned as close to the outlets as possible to avoid rainwater build up on roofs.

Piped or weir perimeter overflows can be acceptable but will not in many circumstances necessarily provide clear and immediate warning to a building user a blockage has occurred.

Where two falls intersect, a minimum finished fall of 1:80 along the mitre should be provided to prevent backfalling.

In the event it is proposed, the use of a stack which has breaks to allow water to flow into an open hopper at each level is to be carefully considered on a case by case basis, as a drainage approach as these outlets risk blockage without proper maintenance. Careful siting of these outlets is critical to the acceptability of this approach to mitigate this risk.

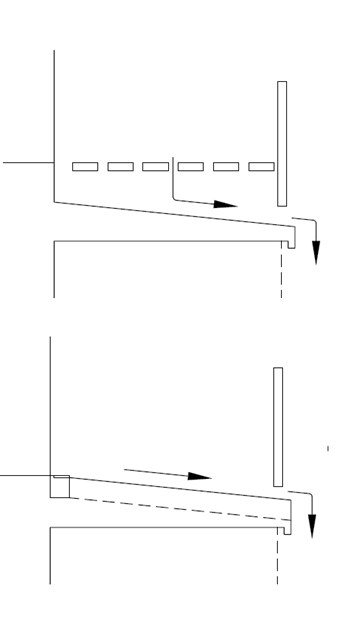

2. Projecting balcony - edge drained

Where a balcony which fully projects from the thermal envelope of the building is specified, positively drained, edge drained or free drained approaches may be employed. Although the Functional Requirements may be met with regard to meeting the minimum standard with the scope of a latent defects structural warranty, it is for the designer to consider the advantages and disadvantages of these approaches and the potential impact to those in and around buildings.

Requirements

- A waterproof threshold upstand of at least 75mm is to be provided. The sill may be level with the pedestrian surface but a gap of at least 10mm between the building envelope and the pedestrian surface is to be maintained.

- Any storm water must disperse at the furthest leading edge of the building and be remote from the façade. Pedestrian substrate boards where provided should be grooved, fall away from the building and run perpendicular to the façade of the building.

- An impervious soffit collection tray is to be provided, falling away from the façade to the leading edge to allow water to discharge away from the building envelope.

- For effective edge drainage, a linear gap is to be provided and must create at least a permanent 20mm wide opening at the leading edge. It should be continuous across the entirety of the width of the balconies leading edge. Chutes or pipes draining directly to open area are not acceptable. Any edge draining approaches should ensure as much as practicable that drainage should not be interrupted, for example by any supporting structure or similar.

- The design of the drainage should not drain from one balcony or roof to another.

- Between non-combustible decking boards gaps between 6mm and 8mm are to be provided between each board. Sizing of gaps it creates a health and safety risk to users – risk of entrapment of walking sticks, stiletto heels, or wheelchairs must be avoided and shown to have been considered in the design. Where decking boards are used at the pedestrian surface level, grooved decking boards are to be provided to promote the shedding of water at the leading edge of the projecting balcony.

- At the base of any stack of any balconies, provision for landscaping drainage must be provided as part of the design to ensure that at the base of the stack, water does not pond at ground or podium level. Paths should be avoided in areas beneath balcony stacks that utilise an edge drained approach or suitable protection for pedestrians provided.

3. Projecting balcony - free draining

Where a free draining approach is used, water is not collected on a membrane or impervious surface but allowed to dissipate through a number of perforations in the balcony substrate, meaning that any hydraulic head of water is avoided. The pedestrian surface is designed to ensure that water is not collected and stored in any way. The pedestrian surface and the water collecting surface are the same.

Requirements:

Balcony surfaces must be orientated to fall away from the building so that water cannot track back toward the building. Standing water is not acceptable.

All projecting balconies where free draining, the support arms must be designed in such a way to prevent water tracking along their underside toward the building. Where this risk is not managed, water may run down the façade, giving a greater likelihood of penetrative damp and staining. Drip edge breaks in the support structure and component design to allow water to track away from the building will mitigate this risk.

A structural upstand of not less than 75mm consisting of a fully bonded waterproof outer membrane or coating, with sufficient 3rd party accreditation for that use is to be provided where level thresholds are required.

A 10mm gap between the façade and pedestrian surface is be provided to avoid run off water overly wetting the façade. Supporting bracketry connections to the main building are to be sealed so that they are weathertight to any potential prevent moisture ingress entering the building.

The free draining approach must meet both of the following criteria:

As-built gaps between planks or slabs should be between 6 mm to 8 mm to achieve effective drainage whilst minimising the risk of discomfort to users with enhanced needs. This spacing must be closely controlled. As-built gaps of 10 mm to 12 mm should be maintained around the perimeter of the pedestrian surface to facilitate good drainage and the sides of any balcony proposed must not abut the weatherproof envelope.

Where the design is to provide perforated draining, the position and sizing of the perforations or open grid should be consistently and regularly applied across the entire surface of the balcony. Openings, either perforated or linear should provide a total free draining area of at least 5% of the overall surface area and provide a solution which ensures water is instantly dissipated from the pedestrian surface.

Where non-combustible decking boards are used at the pedestrian surface level, grooved decking boards are to be provided to promote the shedding of water at the leading edge.

The design should ensure that the supporting structure does not locally interfere with the drainage path or prevent free draining of the balcony area.

Free draining balconies are only acceptable where they project from the thermal envelope of the building and project a maximum of 2500mm from the threshold the balcony serves.

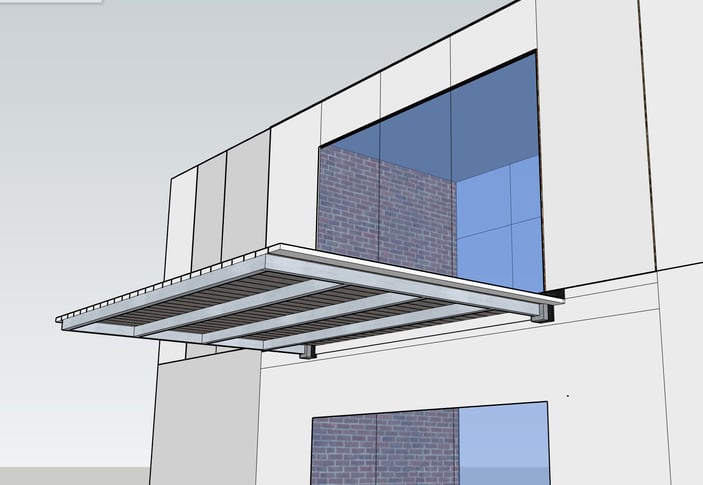

Figure 2 – Yellow denotes upstand. Details relating to non-combustible pedestrian surface and guarding omitted for clarity.

Figure 3 - Underside view (as figure 2 above, details have been removed for clarity)

Installation and testing requirements

Quality assurance and record keeping system should be provided at pre-construction to ensure that standards of workmanship can be demonstrated throughout installation.

Testing and final inspection

For all balconies, prior to request for acceptance it is good practice to test the operation of the balconies with a ‘bucket test.’ This is where a bucket of water is poured over the surface of the balcony and adjacent to the threshold of the door and the outcome recorded to ensure proper operation of the outlet and the overflow where appropriate. Although the volume of water will be greater than in operation, it will show the effectiveness of the drainage approach including drainage paths and highlight any issues relating to the drainage, such as backfalling occurring. It is recommended that this is included in the site Inspection and Test Plan.

Where a waterproofing product such as a membrane or coating has been provided, additional testing may be requested such as peel tests to ensure sufficient bonding has taken place between the substrate and the waterproofing product.

The site team should check the all elements, including the guarding, pedestrian surface and door sills complete for each plot prior to requesting final inspection.

Operations and maintenance

The developer should have in place an Operation and Maintenance manual (O&M) and should identify:

- Definitive confirmation of which party will be responsible for the annual maintenance of the balcony.

- Confirm outline of the drainage approach and a plan location of the outlet and overflow provision where provided.

- Confirm the materials used and their associated 3rd party accreditation or datasheets.

References and further guidance: References (As January 2022)

- Manual to the Building Regulations

- The Building (Amendment) Regulations 2018

- Approved Document B: Approved Document B (fire safety) volume 1: Dwellings, 2019 edition incorporating 2020 amendments

- Approved Document K: protection from falling, collision and impact

- BS 8579:2020: Guide to the design of balconies and terraces

- BS 6180:2011: Barriers in and about buildings - Code of practice

- BS 8204-3:2004 - Screeds, bases and in situ floorings. Polymer modified cementitious levelling screeds and wearing screeds - Code of practice (+A2:2011)

FeRFA Guidance Note: No 15: https://tinyurl.com/2ncjc6ff - Liquid Roofing and Waterproofing Association – Guidance Note No. 3 - Generic Types of Liquid Applied Waterproofing Systems, For Roofs, Balconies and Walkways

- Liquid Roofing and Waterproofing Association – Guidance Note No. 4 Roof, Balcony and Walkway Refurbishment Using Liquid Applied Waterproofing Systems

- Liquid Roofing and Waterproofing Association - Hot Melt Code of Practice - Specification and Use of Hot Melt Monolithic Waterproofing Systems for Roofs, Balconies and Walkways

Back to contents